In the world of online retail, presentation is everything.

With so many custom products competing for attention, the difference between average and exceptional often comes down to one detail: finishing quality.

That’s where spot gloss and raised UV printing come in.

These premium finishes give your products — from packaging and signage to branded merch — a tactile, high-end feel that customers instantly associate with quality.

At CutPrintShip, we help eCommerce sellers and small businesses harness these finishes to elevate their brand identity, increase perceived value, and drive repeat sales.

In this article, we’ll explore what these finishes are, how they work, and how to use them effectively to make your products stand out.

1. What Are Spot Gloss and Raised UV Finishes?

Both spot gloss and raised UV are specialty printing effects achieved through UV-curable clear ink.

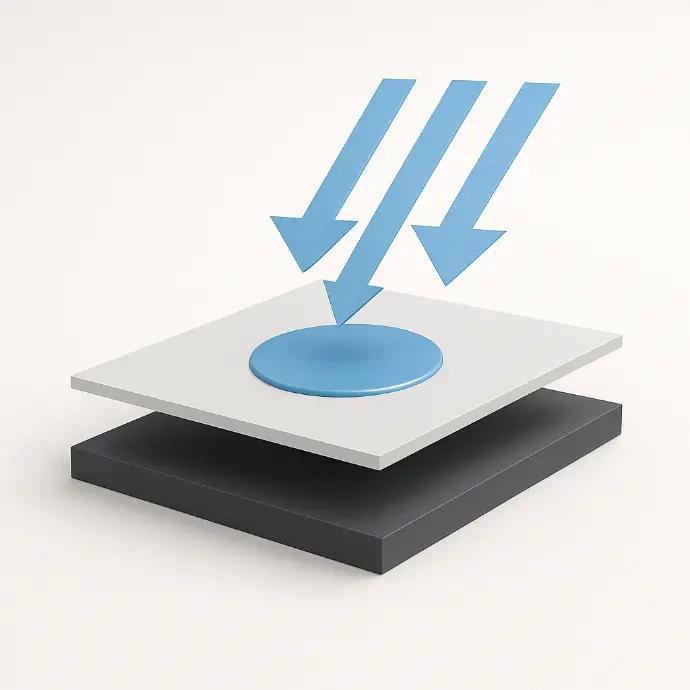

Spot Gloss (also called Spot UV)

Spot gloss adds a high-shine, glossy coating to specific parts of a design — like a logo, text, or background pattern. It creates contrast between glossy and matte areas, resulting in a sleek, professional finish.

Think of it like highlighting key details in your design to catch the light — and your customer’s attention.

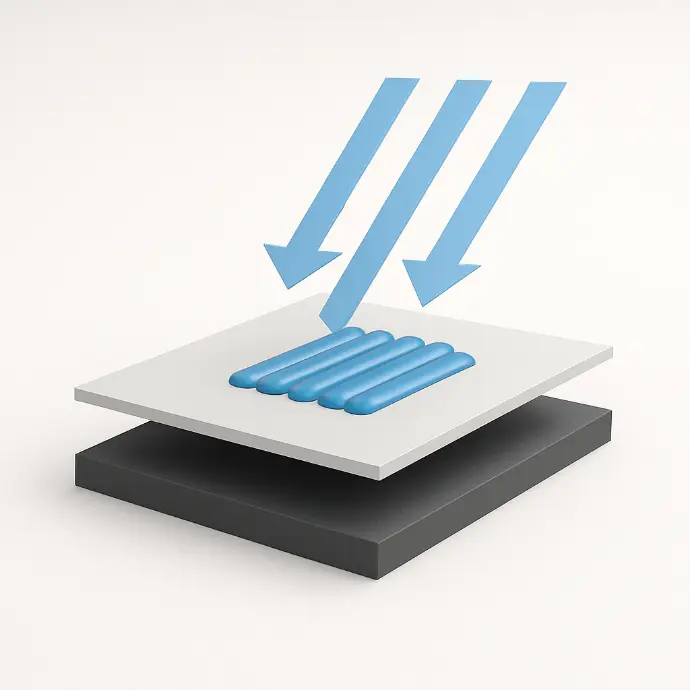

Raised UV

Raised UV uses the same clear UV ink but applies thicker layers, producing a tactile, 3D texture.

The raised areas can be felt under the fingertips, adding physical depth and a luxurious touch.

Think of it like embossing — but with full digital precision and no need for metal dies or molds.

Both effects can be combined to create multi-dimensional, visually stunning designs that not only look premium but feel premium.

2. Why These Finishes Matter for E-Commerce Sellers

When customers shop online, they can’t physically handle your product before purchasing. That means visual and tactile cues in your photos and descriptions must communicate quality.

Spot gloss and raised UV instantly:

- Enhance perceived value

- Differentiate your brand from low-cost competitors

- Encourage higher pricing and better margins

- Reinforce professional, detail-oriented branding

FACT

A recent study by Packaging of the World found that 70% of consumers are more likely to purchase a product if its packaging includes tactile or visual enhancements like gloss or texture.

In short, finishes like these turn your products into experiences — not just objects.

3. The Science Behind the Shine: How It Works

These finishes are made possible by UV printing technology — where special clear ink is applied digitally, then cured instantly using ultraviolet light.

How Spot Gloss Works

- A clear UV varnish is selectively applied to chosen design areas.

- UV light instantly hardens the varnish, creating a glossy highlight.

- The result: sleek contrast between shiny and matte sections.

How Raised UV Works

- Multiple passes of UV varnish are layered in precise alignment.

- Each layer cures instantly, building height and texture.

- The finished surface is tactile, durable, and deeply dimensional.

At CutPrintShip, we control ink layering digitally — allowing pinpoint precision and custom thickness for every design.

4. Applications: Where to Use Spot Gloss and Raised UV

These effects work beautifully across a wide range of products — from marketing materials to physical goods.

E-Commerce Product Applications

Category | Examples | Benefit |

Product Packaging | Boxes, sleeves, hang tags | Premium, gift-worthy presentation |

Signage & Displays | Acrylic signage, plaques | Eye-catching detail under light |

Stationery & Branding | Business cards, invitations | Professional and elegant finish |

Custom Merch | Keychains, coasters, photo panels | Added texture and perceived value |

Home & Décor | Wall art, acrylic prints | Enhanced dimension and light play |

PRO TIP

For packaging and labels, use matte backgrounds to make gloss effects pop even more.

5. Design Tips for Maximum Impact

Spot gloss and raised UV are most effective when used intentionally — to highlight, not overwhelm.

Here are key design strategies for achieving balance and sophistication:

- Highlight Key Elements - Use gloss or raised UV to emphasize logos, product names, or unique artwork details. It draws the eye exactly where you want it.

- Play with Contrast - Gloss shines brightest against matte or uncoated backgrounds. Use minimal gloss for subtle sophistication or full coverage for bold modern effects.

- Create Patterns and Textures - You can use clear UV ink to add invisible patterns or textures — visible only when light hits them at the right angle. It’s a perfect “wow factor” for packaging and premium prints.

- Combine with Color Layers - Try printing gloss on top of color for depth or over metallic ink for reflective drama. Raised UV over dark backgrounds looks especially striking.

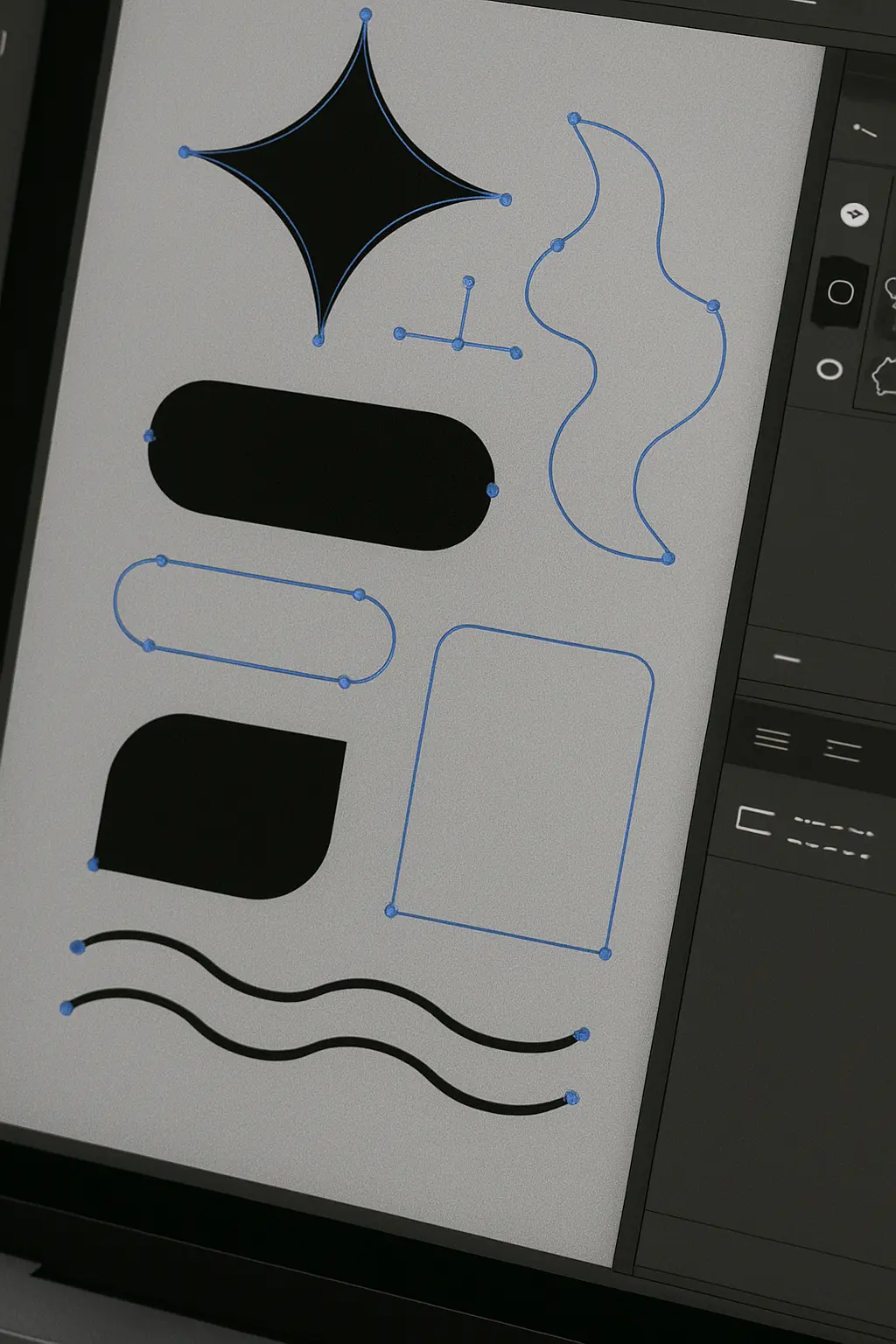

- Keep File Prep Clean - Use vector paths and separate layers labeled “Gloss” or “Raised UV” for accurate placement.

At CutPrintShip, our prepress team reviews every file to ensure the finish layers align perfectly for flawless results.

6. Pricing and Perceived Value

Adding specialty finishes increases production costs slightly — but the perceived value multiplies significantly.

Example Breakdown

Product | Base Price | With Spot Gloss | With Raised UV |

Acrylic Sign | $25 | $32 | $38 |

Product Box | $12 | $18 | $22 |

Business Card Pack | $30 | $45 | $55 |

That’s a small cost increase for a premium upgrade customers can both see and feel.

Because these finishes photograph beautifully, they also improve online conversion rates by making your listings more visually compelling.

PRO TIP

Offer “premium finish” upsells on your product pages — customers often choose the upgrade when shown side-by-side images.

7. Combining Spot Gloss and Raised UV

The most striking designs often use both techniques together: spot gloss for reflective highlights and raised UV for tactile dimension.

For example:

- A matte black business card with glossy logo text and raised UV accent lines

- A product box with smooth gloss elements and textured logo emboss

- An acrylic sign with layered gloss patterns that catch the light

This combination creates a dynamic, luxury aesthetic that online shoppers associate with high-end brands.

8. The Technical Side: File Setup

Proper setup ensures your finishes print exactly as designed.

File Prep Checklist

Use vector shapes for gloss areas

Label layers clearly (e.g., “Gloss”, “Raised UV”)

Ensure perfect alignment with the base artwork

Avoid gradients or transparency in finish layers

Use solid fills (100% K) to define gloss areas

For best results, send artwork in PDF or AI format. Our production team can also assist with converting flat artwork into raised UV-ready files.

9. Marketing Your Premium Finishes

Once your products feature raised UV or gloss effects, showcase them like the luxury items they are.

Marketing Tips

- Use macro photography that captures light reflection and texture

- Create before-and-after product shots to highlight the difference

- Include phrases like “tactile gloss finish” or “luxury raised UV texture” in your descriptions

- Offer limited-edition premium versions of your bestsellers

These subtle upgrades communicate value and allow you to justify higher pricing — while giving customers something worth showing off.

10. Why CutPrintShip Is Your Perfect UV Finishing Partner

Not all print providers are equipped for precision UV finishing. At CutPrintShip, we’ve invested in advanced UV systems that support:

- Spot gloss and raised UV in one pass

- Precise layer registration for perfect alignment

- Custom height control for texture depth

- High-resolution detail for logos, lines, and typography

We help eCommerce sellers, designers, and small businesses turn everyday prints into premium products that sell faster and command higher prices.

Conclusion

Spot gloss and raised UV printing are more than aesthetic upgrades — they’re powerful branding tools.

These finishes transform ordinary products into extraordinary experiences, elevating your brand and boosting customer perception.

Whether you’re designing packaging, signage, or merchandise, adding texture and shine can be the difference between being seen — and being remembered.

With CutPrintShip, you can bring these finishes to life at scale — quickly, affordably, and with flawless precision.