The Beginner’s Guide to Laser Cutting for Custom Products

If you’ve spent any time browsing handmade marketplaces or scrolling through personalized product shops online, you’ve probably noticed a surge in laser-cut items—from engraved cutting boards and jewelry to custom signage, décor, and packaging. Laser cutting has become one of the most popular production methods for makers and ecommerce sellers because it blends precision, speed, and versatility in a way few other tools can match.

Whether you’re a new designer exploring creative tools, a seller looking to expand your product lineup, or a hobbyist ready to level up your craft, understanding the fundamentals of laser cutting will give you a huge advantage. This beginner-friendly guide breaks down everything you need to know: how laser cutting works, the types of machines available, materials you can use, costs, applications, and why laser cutting is such a powerful option for custom product businesses.

What Is Laser Cutting? A Simple Explanation

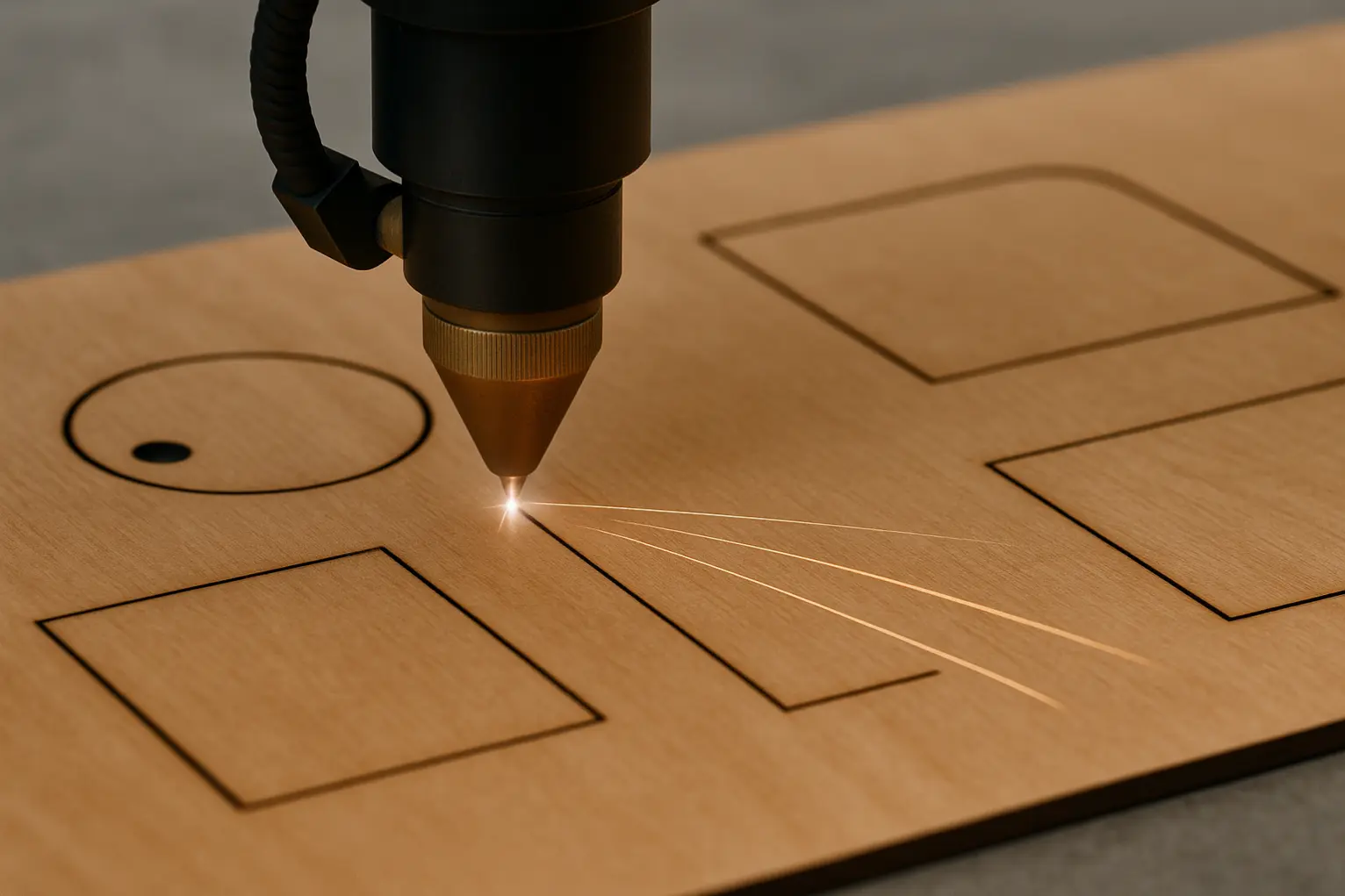

Laser cutting is a digital fabrication process that uses a high-powered, focused beam of light to cut, engrave, or mark materials. Unlike traditional cutting tools—such as blades, drills, or saws—the laser never physically touches the material. Instead, it creates clean, precise cuts by vaporizing or melting the surface along a pre-programmed path.

At its core, laser cutting converts digital designs (typically created in vector format) into real-world products. This makes it ideal for anyone who wants to recreate designs accurately, repeatedly, and at scale.

Laser cutting typically includes three operations:

- Cutting - A full cut goes entirely through the material, creating crisp edges and detailed shapes.

- Engraving - Engraving removes or etches the top surface only, producing text, logos, or textured designs.

- Scoring or Line Engraving - This creates shallow lines ideal for folding, alignment, or decorative detailing.

For custom product makers, this combination of precision and flexibility opens up limitless creative possibilities.

How Laser Cutting Works: From Design to Finished Product

Laser cutting follows a clear, straightforward workflow:

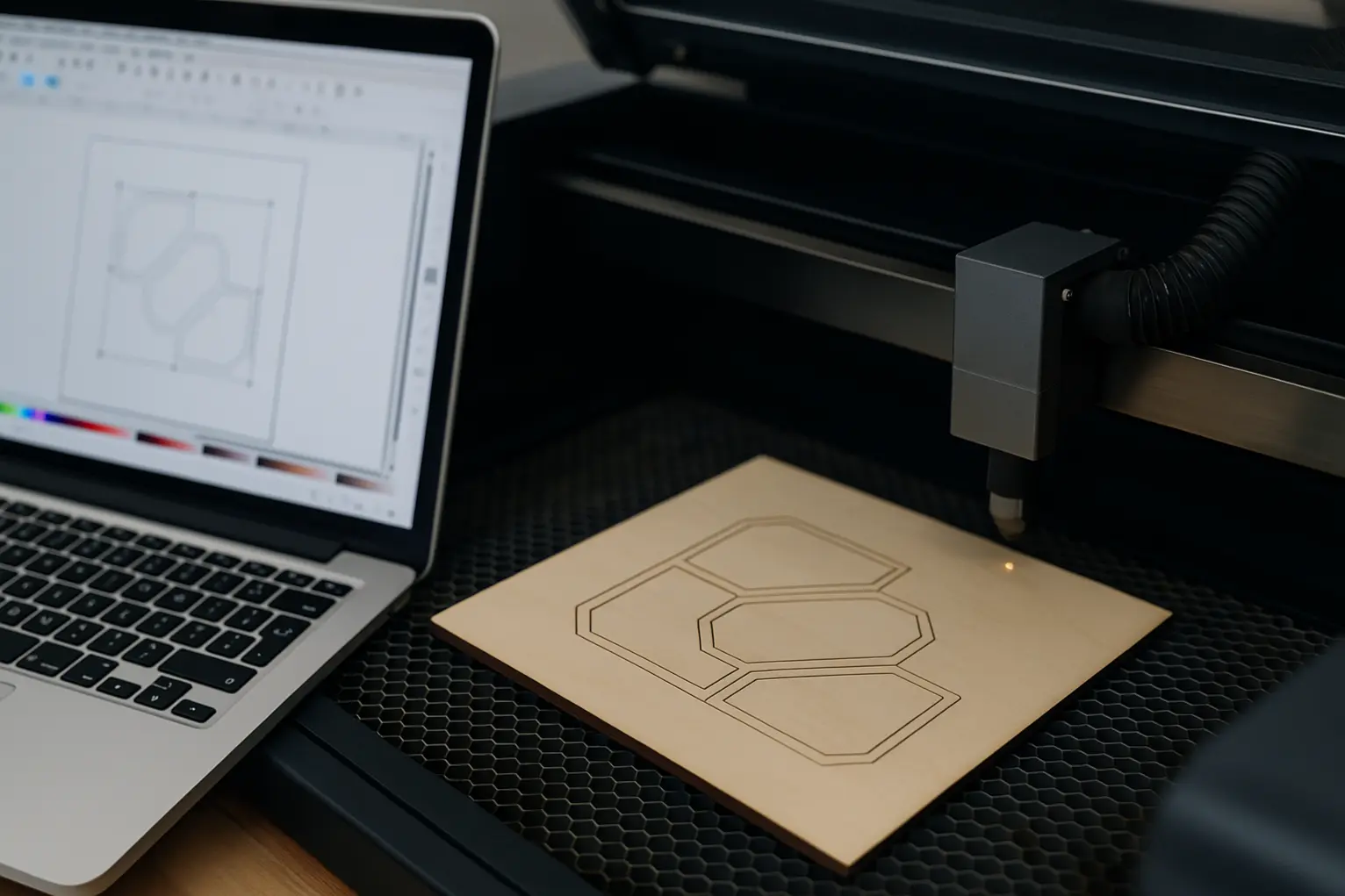

- Create or import a digital design - Most creators use vector software such as Adobe Illustrator, CorelDRAW, Inkscape, Affinity Designer, or specialized laser-cutting tools like LightBurn. Your design file usually needs to follow basic settings for lines, colors, and thickness so the laser knows what to cut versus engrave.

- Choose your material - Different materials require specific power levels and speeds. Wood, acrylic, and leather are especially popular because they cut cleanly and look great engraved.

- Configure laser settings - The machine operator sets speed, power, passes, and focus. These values determine how deeply the laser cuts or engraves the material.

- Run the job - Once settings are dialed in, the laser follows the digital path with extreme precision—producing the final object.

- Finishing and quality checks - Some products may need sanding, cleaning, sealing, or assembling. For ecommerce sellers, this is also when branding or packaging is added.

This digital-to-physical workflow makes laser cutting perfect for both one-off custom pieces and small-batch production.

Popular Materials Used in Laser Cutting

One of the biggest advantages of laser cutting is its compatibility with a wide range of materials. Here are some of the most common choices for custom product creation:

Wood

- Types: birch plywood, maple, walnut, MDF, bamboo

- Ideal for: signage, ornaments, décor, toys, home goods

- Benefits: natural look, engraves beautifully, strong, easy to finish

Acrylic (Plexiglass)

- Ideal for: signage, jewelry, displays, tags, LED edge-lit lamp designs

- Benefits: polished cut edges, wide color options, durable, professional-looking

Leather & Faux Leather

- Ideal for: patches, wallets, accessories, journals

- Benefits: rich contrast when engraved, durable, premium feel

Cardboard & Paper

- Ideal for: packaging prototypes, stencils, invitations

- Benefits: inexpensive, fast to cut, lightweight

Fabric & Felt

- Ideal for: apparel, patches, crafts, décor

- Benefits: sealed edges (synthetics), clean cuts, customization

Metal (Marking only for most machines)

- Ideal for: tags, tumblers, nameplates

- Benefits: long-lasting, professional appearance

Knowing which materials match your brand or product idea is key to launching a successful line of laser-cut items.

What Products Can You Make With Laser Cutting?

Laser cutting excels at producing highly customized, personalized, and repeatable products—exactly what online shoppers want.

Here are some of the most popular use cases:

1. Personalized Gifts

- Engraved cutting boards

- Family name signs

- Customized photo frames

- Monogram ornaments

These are incredibly popular during holidays and wedding season.

2. Home Décor

- Wall art

- LED acrylic lamps

- Shelf sitters

- Key holders

- Patterned screens or accents

Laser-cut décor has become a top seller on Etsy, TikTok Shop, and Shopify stores.

3. Jewelry & Accessories

- Earrings

- Pendants

- Keychains

- Bag tags

- Leather patches

Lightweight materials like acrylic and wood make these easy to produce and ship.

4. Business & Branding Products

- Engraved coasters

- Custom signage

- Merchandise tags

- Promotional items

- Small businesses love custom branding options.

5. Craft Blanks & Supplies

- Shapes for other makers

- Earring blanks

- Risers and display stands

- Shopping basket tags

Selling blanks is a popular niche with recurring customers.

Laser cutting is one of the few tools that appeals equally to consumers, businesses, and other makers—creating multiple revenue streams for sellers.

Why Laser Cutting Is Ideal for Ecommerce Sellers

If you’re building a custom product business, laser cutting offers several major advantages:

- Rapid Production With Minimal Setup - Because laser cutting uses digital files, switching designs is instant—no molds, templates, or physical tooling required.

- High Precision and Repeatability - Products come out consistent every time, which is essential for brand quality.

- Easy Customization - Add names, dates, or designs on the fly without interrupting production workflows.

- Scalable for Small Businesses -You can produce: one personalized order a small batch or hundreds of identical pieces using the same equipment.

- Access to Niche Markets - Shoppers want products that feel personal. Laser cutting makes it affordable to offer made-to-order items without high overhead.

- Perfect for “Print-on-Demand” Style Selling - Many makers now use third-party laser cutting services to fulfill orders, allowing them to sell without owning a machine.

How Much Does Laser Cutting Cost?

Costs vary depending on whether you own a machine or use a service, but here’s a simple breakdown.

Buying Your Own Laser

Consumer-grade CO₂ lasers range from $500 to over $10,000, depending on features, power, and size. Popular brands include:

- Glowforge

- xTool

- OMTech

- Full Spectrum Laser

- Beyond the machine, you may need:

- ventilation

- materials

- software

- finishing supplies

It’s an upfront investment but provides full control and higher profit margins.

Using a Laser Cutting Service

If you’d rather outsource production, companies like Ponoko, Sculpteo, and local makerspaces offer affordable cutting with:

- no equipment cost

- no maintenance

- professional finishing

You typically pay for:

- laser time

- material cost

- labor or setup

For many ecommerce sellers, outsourcing is a low-risk way to test product ideas before investing in a machine.

What Skills Do You Need to Get Started?

The good news: you don’t need an engineering background to use a laser cutter. Most people can become proficient with basic training.

Helpful skills include:

- Vector design basics

- Understanding materials

- Knowing how to adjust laser settings

- Simple finishing and assembly techniques

If you’re selling online, skills like branding, photography, and packaging also help you stand out.

Plenty of makers start with zero experience and build profitable product lines in months.

Tips for Beginners: How to Learn Laser Cutting Faster

Here are some quick tips to accelerate your learning curve:

- Start with easy materials like 1/8” plywood or acrylic.

- Keep a notebook of settings for each material.

- Begin with simple shapes and gradually try more complex designs.

- Join maker communities on TikTok, Reddit, and Facebook.

- Watch tutorials for your specific machine brand.

- Don’t skip safety gear—especially ventilation.

- Test designs on scrap material before running full projects.

Laser cutting is a skill you build over time, and every project teaches you something new.

Is Laser Cutting Right for Your Business?

If you want to create beautiful, personalized products that stand out in the ecommerce marketplace, laser cutting is absolutely worth exploring. It offers:

- unmatched customization

- professional results

- strong profit margins

- scalable production

- wide material variety

For makers, designers, and small business owners, it’s one of the most accessible and versatile fabrication tools available today.

Whether you start with a small desktop machine or outsource your production to a service, laser cutting can help you create unique products that customers love—and buy repeatedly.